If you can think it we can make itCustom Mechanical Design

We employ best practices in CAD/CAM design and simulation.

From product preliminary design, through the development and even industrialization for small production runs, our team can deliver any kind of mechanical design.

We have a varied skillset and can rapidly deploy our specialists to quickly deliver your project at each development stage.

Through the years we have constructed a network of trusted partners that can help us speed up the development process by providing a variety of prototyping, reverse engineering, and manufacturing services with little to no lead time.

Our expertise has been built following the strict standard and requirements of the automotive industry.

We’re based in Turin at the heart of the Italian automotive district, and in our young history, we worked with major manufacturers, boutique car makers, internationally renowned car designers, and racing teams.Even though our mechanical skill set revolves around the automotive sector, we have completed projects across the whole spectrum of manufacturing sectors.

Our diverse background, flexible attitude, and expertise let us innovate and complete even the most demanding product development projects by reaching perfect integration between mechanical design and software.

Our peculiar skills allow us to tailor the design around your needs while staying within your budget.

Our designs are generally modeled using Dassault Systemes’ CATIA, an industry-standard software employed by all major manufacturers.

At the client’s request, we can discuss whether to use different solutions to cater to particular needs.

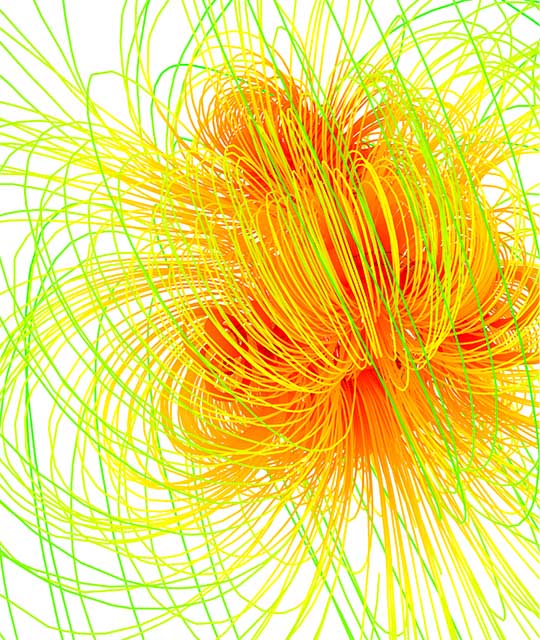

Bespoke multiphysics simulations for your designsSimulation

We offer a solid array of multiphysics simulation solutions.

Simulations can be employed for a wide variety of reasons, they can help your organization validate and optimize design ideas before testing them or going into production thereby reducing costs and speeding up the development and industrialization processes.

We provide a variety of simulation services.

We employed finite element analysis in various fields including but not limited to computational fluid dynamics, structural mechanics, and even magnetostatics.

We also developed coupled-physics analysis models for pretesting and validation of different industrial designs determining flow-induced vibrations and simulating fluid flow with heat transfer.

Our team has participated, at various levels, in the aerodynamic design, testing, and optimization of both production and racing vehicles, in the design and validation of battery packs for electric mobility, and in the simulation of permanent magnet based levitation.

We normally employ a set of open-source packages such as OpenFOAM, which have proven time and time again to be fast, precise, and economically viable solutions for most applications.

At the request of the customer or for special needs, we can use commercial solvers and preprocessors to match exotic requests.